“Game changing technology” could change the face of European manufacturing

The rate of technological advancement has only increased in the 21st century, and with this advancement comes the possibility of new “game changing technology”. Game changing technology has the potential to disrupt not only the product level, but the entire production process. This next step in the manufacturing sector has been called “Industry 4.0”.

A new report from the Future of Manufacturing in Europe (FOME) project, which was proposed by the European Parliament and delegated to Eurofound by the European Commission, has been released which summarizes the possible impact of five game changing technologies on not only production but also the consequences for individuals employed in the manufacturing sector in Europe.

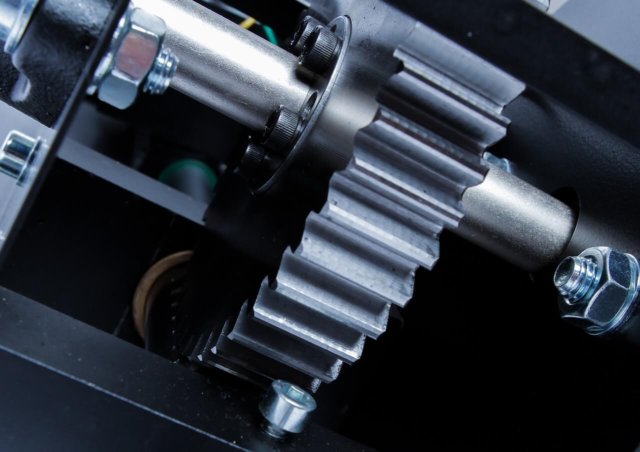

The five game changing technologies described in the report include: advanced industrial robotics (AIR), additive manufacturing (AM), industrial internet of things (IIoT), electric vehicles (EV), and industrial biotechnology (IB). A main characteristic of these technologies, especially AIR, AM and IIoT, is their ability to bring manufacturing into the digital age.

They give “the possibility of gathering an enormous quantity of digital data about processes, thus linking manufacturing with the digital realm.” These technologies are still in their infancy. At the same time, EV and IB are having more impact on more well-established industries.

These technologies’ effect on the labor market is expected to shift employment demand away from traditional manufacturing work such as working on an assembly line to necessitating a smaller number of more highly skilled employees.

While the job loss is predicted as machines replace labor, there will be an increase in demand for labor in the technology supply firms. In order to facilitate the development of these new technologies and bring the labor force up to speed, many EU members have begun developing national strategies with sizable budgets.

For example, Germany’s “Plattform Industrie 4.0” program has been granted a budget of €200 million with the goals of reducing industry segregation and transforming research agenda into practice.” While Germnay’s program has been granted the largest budget, France, Italy, and Spain, among others, have similar programs now in place.

The main conclusions of the report focus on a few key points. Firstly, in the future, manufacturing and production processes will become increasingly digital and less mechanical. Some of the greatest possibilities are that digital technology will allow for the design and testing of products and processes completely virtually, in addition repair on machinery will be able to be completed remotely.

Secondly, Competition in manufacturing will be more focused on the capacity to automate an increasing number of processes and less on the cost of labor as it is today. Importantly, this could shape the way for bringing manufacturing back to Europe from the cheaper labor markets abroad. However, at the same time, the increased use of digital technology brings the need for a greater importance on managing data security vulnerabilities.

Lastly, the report stresses the need for adoption and observance of industry standards and protocols in order to increase the potential benefit to SMEs. As these technologies develop, they bring with them the opportunity to invest in potentially lucrative new businesses in the technology supply side as well as in the manufacturing firms who stand to benefit from the implementation of such technology.

For more information: Eurofound